Cutting-Edge Technology: The Optical Fibre Diameter Analyser and Its Impact on the Industry

Cutting-Edge Technology: The Optical Fibre Diameter Analyser and Its Impact on the Industry

Blog Article

Just How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes stands for a significant innovation in quality control methods. By offering real-time, precise measurements of Fibre diameters, this technology addresses the vital demand for consistency in manufacturing standards.

Importance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is critical in the area of optical Fibre technology, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capacity, depletion, and overall transmission effectiveness. Precision in determining Fibre Diameter makes sure that the optical homes are maintained within specified tolerances, which is important for optimal signal integrity.

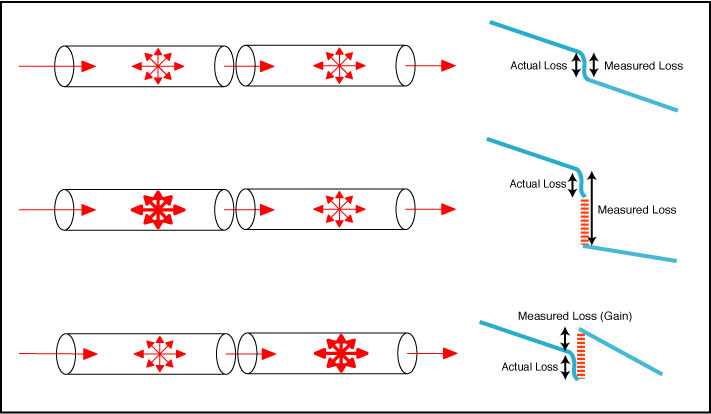

Variants in Fibre Diameter can lead to increased losses due to scattering and modal dispersion, affecting the top quality of data transmission. In high-speed interaction systems, such inconsistencies can lead to significant deterioration of signal top quality, leading to data errors and minimized performance. Regular Fibre Diameter is essential for compatibility with connectors and splicing technologies, which are essential parts of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily depend on precise Diameter dimensions to ensure conformity with industry requirements. By implementing robust measurement techniques, manufacturers can enhance product integrity, decrease waste, and enhance total system performance. Thus, the significance of Fibre Diameter dimension can not be overstated, as it acts as a cornerstone in the improvement of optical Fibre modern technology and its applications in modern-day interaction networks.

Exactly How the Analyser Functions

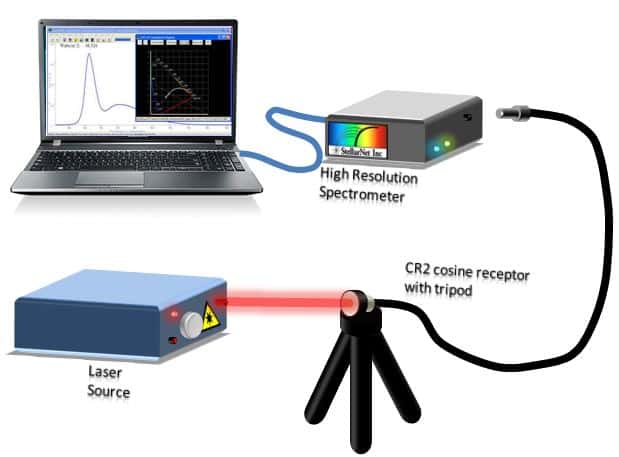

The reliable dimension of Fibre Diameter depends on advanced logical techniques that guarantee precision and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser innovation and advanced photo processing formulas to accurately assess the Diameter of fibres as they are created

Initially, a laser light beam is guided at the moving Fibre, developing a cross-sectional shadow. The analyser catches this shadow using high-resolution video cameras placed tactically along the manufacturing line. The caught photos are then processed in real-time to identify the Fibre's Diameter with phenomenal accuracy.

The system uses advanced algorithms that represent various elements, including variants in light intensity and ecological conditions, to improve measurement dependability. It can spot minute adjustments in Diameter, such as fluctuations that might happen throughout the manufacturing procedure.

Moreover, the analyser can handling multiple fibres at the same time, enhancing throughput without jeopardizing accuracy. By giving immediate responses on the Diameter, the Optical Fibre Diameter Analyser plays a vital duty in keeping stringent quality assurance criteria, guaranteeing that the last item fulfills market specifications and client requirements.

Advantages of Real-Time Surveillance

While traditional methods of checking Fibre Diameter often entail lengthy post-production checks, real-time monitoring considerably boosts the effectiveness and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive technique permits producers to identify inconsistencies in Fibre Diameter as they take place, as opposed to waiting until production is full to assess quality

By constantly gauging the Diameter throughout manufacturing, suppliers can ensure that the fibres fulfill stringent specs, causing minimized irregularity and boosted uniformity. Real-time tracking also enables prompt rehabilitative activities to be taken, lessening waste and protecting against malfunctioning fibres from entering the supply chain.

In addition, this modern technology promotes boosted data collection and analysis, giving understandings right into manufacturing trends and potential locations for enhancement. Such data-driven decision-making equips makers to enhance procedures and preserve high criteria of high quality control.

Additionally, real-time monitoring fosters a society of constant enhancement within the production setting. Workers are more engaged when they can see the impact of their job in real-time, leading to enhanced liability and a commitment to excellence. Overall, the application of real-time monitoring systems in optical Fibre production translates to premium item top quality and raised consumer satisfaction.

Impact on Production Efficiency

Executing optical Fibre Diameter analysers substantially boosts manufacturing effectiveness by enhancing the manufacturing process. These tools facilitate continuous monitoring of Fibre Diameter, allowing producers to find variances in real-time. By determining disparities without delay, assembly line can be adjusted rapidly, decreasing downtime and reducing the likelihood of creating malfunctioning products.

Furthermore, the assimilation of these analysers into the production operations allows much better source allotment. With exact Diameter dimensions, operators can enhance product use, making certain that resources are not squandered on problematic fibres. This accuracy additionally adds to less revamp and scrap, eventually reducing production costs.

The automation offered by optical Fibre Diameter analysers decreases reliance on manual assessments, which are vulnerable and typically taxing to human error. As read here an outcome, staff members can concentrate on more tactical jobs, enhancing general performance.

Furthermore, the information created from these analysers can educate procedure enhancements and assist in far better decision-making. By assessing patterns in Fibre Diameter variants, suppliers can implement proactive procedures to improve production techniques and keep constant quality. In summary, optical Fibre Diameter analysers play an important duty in boosting production effectiveness, leading to greater high quality output and boosted productivity.

Study and Success Stories

Across various fields, study highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One famous example is a leading telecoms business that encountered challenges with inconsistent Fibre sizes, leading to boosted being rejected rates. By incorporating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, leading to a 30% decrease go to this web-site in problems and considerable cost savings.

Furthermore, a research study organization concentrating on innovative materials utilized optical Fibre Diameter analysers to improve their speculative procedures. The analyser's capability to provide detailed insights into Fibre consistency enabled the growth of cutting-edge materials with better efficiency characteristics.

These success stories emphasize the necessary duty of optical Fibre Diameter analysers in enhancing quality assurance, enhancing production performance, and driving technology throughout varied markets.

Final Thought

To conclude, the Optical Fibre Diameter Analyser plays an essential duty in enhancing quality assurance within Fibre manufacturing. By providing accurate, real-time measurements and promoting immediate rehabilitative activities, this innovation dramatically reduces variability and reduces waste. The execution of such innovative devices fosters a culture of constant enhancement and operational effectiveness, inevitably making sure compliance with market standards and maintaining competition. As shown via different instance research studies, the analyser confirms necessary for accomplishing exceptional item quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers permitted for stringent high quality control, guaranteeing that the created fibers satisfied exacting market requirements.In conclusion, the Optical Fibre Diameter Analyser plays a crucial duty in enhancing top quality control within Fibre production.

Report this page